BOTTLING Machinery Professional Beverage Production Line

This filling line is special for 3-5 gallon barreled drinking water , with model QGF series of full sets of filling and packing machines .It integrates barrel washing ,filling and capping into one unit .In order to achieve the purpose of washing and sterilizing.

It also can automatically carry out the barrel ,washing ,sterilizing ,filling, capping , counting and products discharging ,with complete function , modern design and high degree of automation.

It is a new kind of barreled water auto-producing line , which integrates mechanism , electricity ,and pneumatics technologies together.

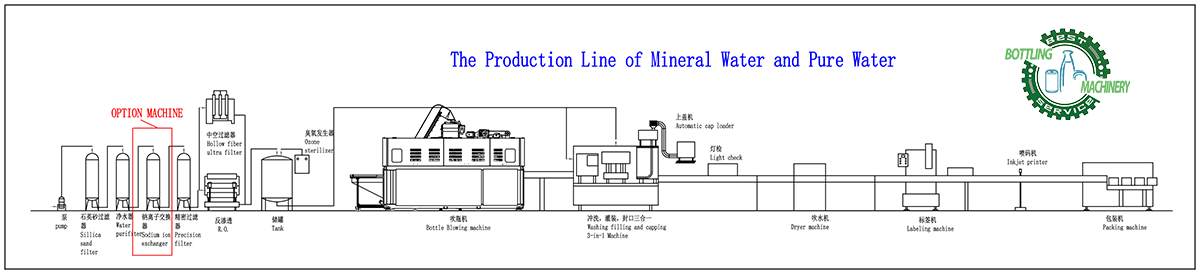

It’s used to produce 3-10l plastic bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery. It includes bottle blowing machine, water treatment, water bottle filling and packing system and so on. It is specially designed for producing bottled drinks, equip with advanced intelligent operating system, stable filling and rehydration function, vial automatic card bottle function, wide application range and convenient adjustment, closed and pollution-free filling process.

This filling line is special for 3-5 gallon barreled drinking water , with model QGF series of full sets of filling and packing machines .It integrates barrel washing ,filling and capping into one unit .In order to achieve the purpose of washing and sterilizing.

It also can automatically carry out the barrel ,washing ,sterilizing ,filling, capping , counting and products discharging ,with complete function , modern design and high degree of automation.

It is a new kind of barreled water auto-producing line , which integrates mechanism , electricity ,and pneumatics technologies together.

| Model | CGF8-8-3 | CGF12-12-4 | CGF18-18-6 | CGF24-24-8 | CGF32-32-8 | CGF40-40-10 | CGF50-50-12 | CGF60-60-15 |

|---|---|---|---|---|---|---|---|---|

| Filling speed | 3000BPH | 4000 BPH | 6000-7000 BPH | 10000-12000 BPH | 13000-15000 BPH | 15000-18000 BPH | 20000-22000 BPH | 24000-25000 BPH |

| Suitable bottle | 100-2000ml | 100-2000ml | 100-2500ml | 100-2500ml | 100-2500ml | 100-2500ml | 100-2500ml | 100-2500ml |

| Space needed | 200㎡ | 200㎡ | 600㎡ | 1000㎡ | 2000㎡ | 2500㎡ | 3000㎡ | 3800㎡ |

| Total power | 75KW | 90KW | 180KW | 190KW | 250KW | 350KW | 450KW | 550KW |

| Operate workers | 6 | 6 | 5 | 5 | 5 | 5 | 5 | 5 |

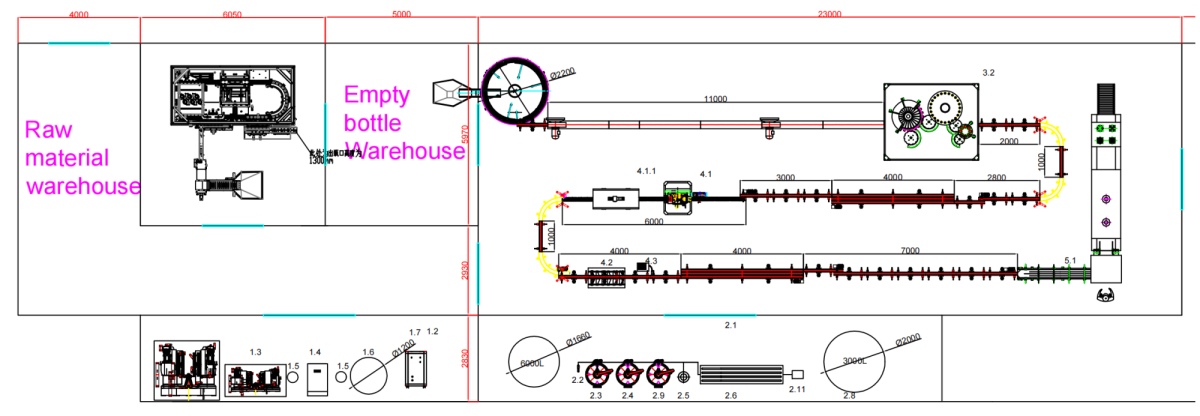

Factory Layout

Bottle Shaping

Label Graphing

Profit Calculation

Business Management

In-person Tech Support

The Automatic PET Bottle Making Machine is designed to cater to a diverse range of shapes and sizes, from 100 ml to 2000 ml. Its broad applicability extends to the manufacturing of bottles for mineral water, carbonated beverages, juice and cola. This machine offers exceptional adaptability in the production of bottles, thereby minimizing content repetition.

Blowing process:

Automatic preforms feeding

Preform heating in the tunnel

Preform Blowing in the mould

Shaped bottle and outlet

The machine possesses the capability to treat diverse varieties of source water, transforming it into pure, potable drinking water. It is ideal for deployment in enterprises engaged in the sale of purified water, bottle filling operations, community water supply systems, domestic water supply networks, and sachet water packaging ventures, among others.

The complete purification process involves several stages, starting with the raw water pump, followed by the multimedium (quartz sand) filter, the active carbon filter, the water softener, the cartridge filter, the high-pressure pump, and ultimately, the reverse osmosis (RO) system. All these integral components are ingeniously housed within a single SUS304 body.

This PET bottle 3-in-1 machine combines the functionalities of rinsing, filling, and capping into a single system. Leveraging advanced international technology and tailored to meet the specific requirements of filling processes for mineral water, purified water, and similar products.

Integrated within this machine are three primary functions: 1. Thoroughly rinsing the empty PET bottles, 2. Precisely filling the rinsed bottles, 3. Effectively capping the filled bottles.

We provide a diverse range of bottle labeling machines tailored to meet your specific requirements. Our machines are designed to accommodate various labeling types, including PVC sleeve labels, self-adhesive labels, OPP labels, and paper labels.

Choose from our extensive selection of bottle labeling machines to find the perfect match for your needs. Our machines offer exceptional versatility, allowing you to apply different types of labels with ease.

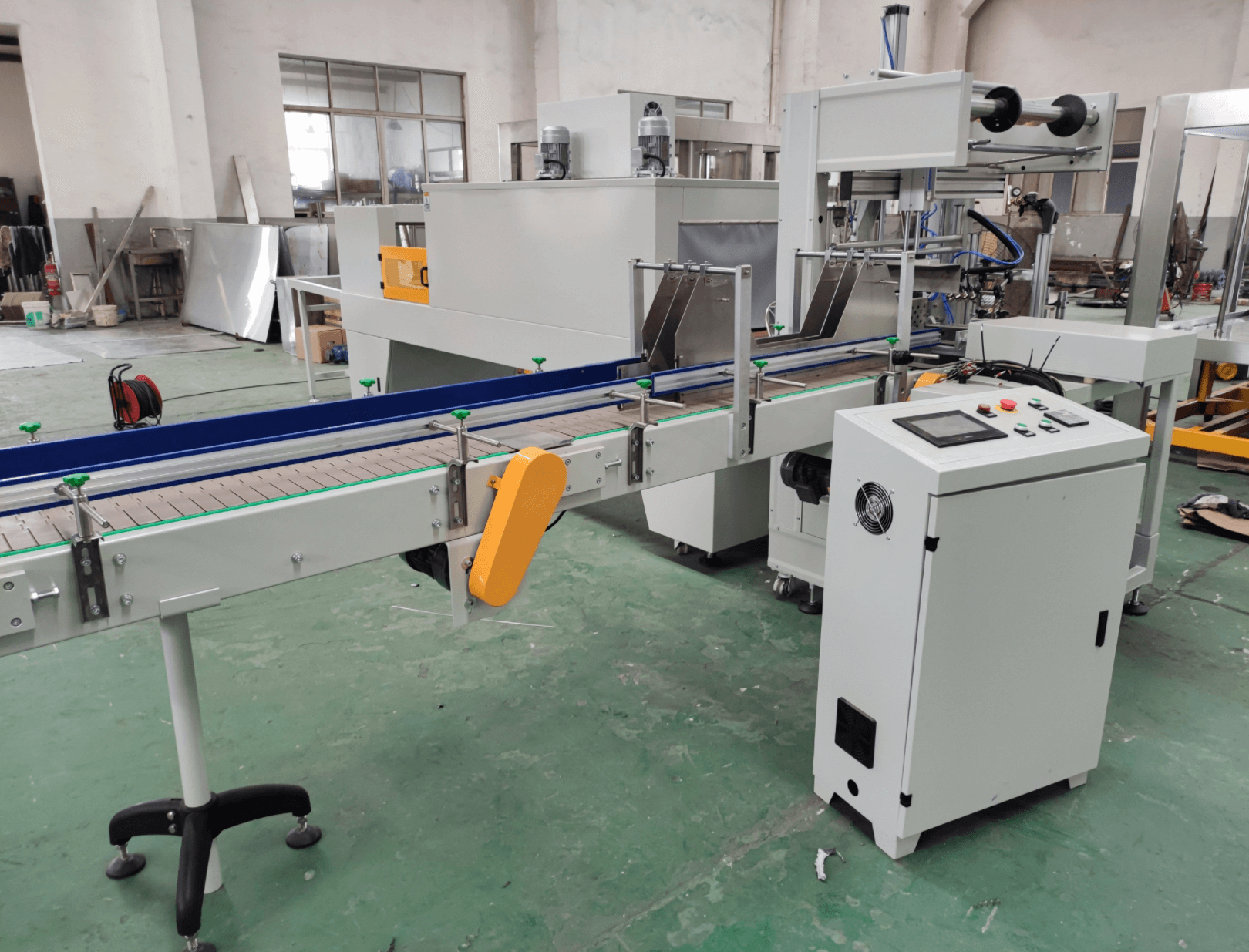

Situated at the final stage of the production line, our film shrink wrapping machine efficiently packages bottles into cohesive bundles. This versatile machine can accommodate various bottle combinations, such as 2*3, 3*4, 4*6, and more. In addition to this, we offer a vibrant range of film wrapping machines, tray packing machines, and carton packing machines to cater to diverse packaging needs.