BOTTLING Machinery Professional Beverage Production Line

This filling line is special for 3-5 gallon barreled drinking water , with model QGF series of full sets of filling and packing machines .It integrates barrel washing ,filling and capping into one unit .In order to achieve the purpose of washing and sterilizing.

It also can automatically carry out the barrel ,washing ,sterilizing ,filling, capping , counting and products discharging ,with complete function , modern design and high degree of automation.

It is a new kind of barreled water auto-producing line , which integrates mechanism , electricity ,and pneumatics technologies together.

This production line consists of equipment such as a fruit washing machine, crusher, juicer or pulper, and colloid mill. It is designed to extract juice as the raw material for fruit juice production. The fruit washing machine cleans the fruits, while the crusher breaks them down into smaller pieces. The juicer or pulper extracts the juice from the fruit, and the colloid mill helps refine the juice by grinding it to a smooth consistency.

This processing plant includes a sugar melting pot, blending tank, homogenizer, deaerator, and ultra-high temperature (UHT) instant sterilizer. Each process in this plant is dedicated to handling the juice. The sugar melting pot dissolves sugar for sweetening the juice, while the blending tank combines different juices or ingredients. The homogenizer ensures uniform texture, and the deaerator removes air bubbles. Finally, the UHT instant sterilizer rapidly heats the juice to a high temperature for a short time, effectively killing any microorganisms.

A steam boiler can be fueled by various sources such as gasoline, kerosene, diesel, etc. It generates steam to provide a heating source for many equipment in the fruit juice production line. The steam produced by the boiler is used for tasks such as heating the fruit processing equipment, including the sugar melting pot, homogenizer, and sterilization equipment, helping maintain the required temperatures for efficient production.

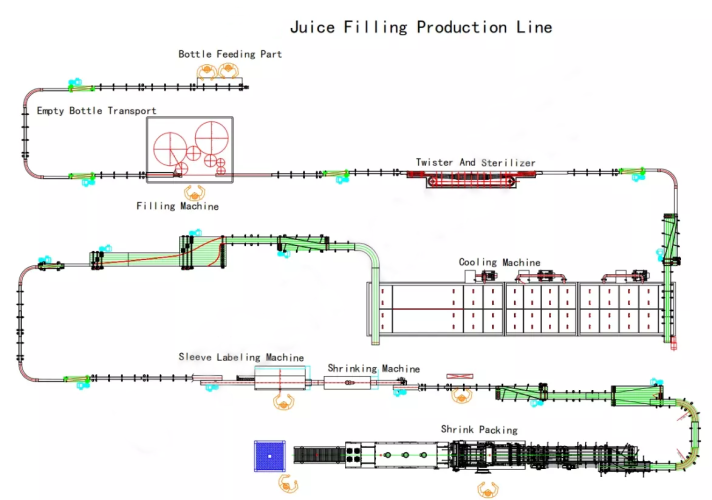

The bottle juice filling machine, also known as a 3-in-1 filling machine, incorporates functions for rinsing, filling, and capping bottles. The specific model of the machine depends on factors such as the bottle type (glass or plastic), the presence of pulp/jelly in the juice, and the desired filling temperature. This machine efficiently and accurately fills bottles with juice, ensuring proper sealing and maintaining product quality.

After the juice is filled into bottles, the bottles go through a bottle inverting machine and a spray-type pasteurization machine. The bottle inverting machine flips the bottles 90 degrees, allowing the high-temperature juice to sterilize the inside of the bottle caps. The spray-type pasteurization machine then cools the juice bottles from the high temperature to around 35 degrees Celsius, effectively preserving the quality and extending the shelf life of the juice.